One thing unites nearly every industry in the world today, from mining to agriculture, to nuclear power: they all generate waste. Dr. Fady Abdelaal is working to ensure the systems we use to contain that waste are robust enough to prevent environmental disaster and durable enough to do so for the foreseeable future.

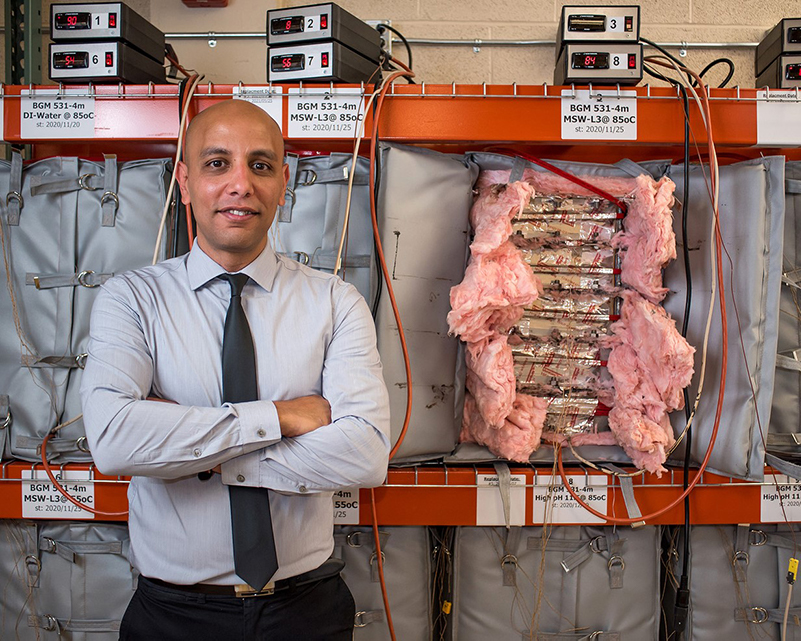

As an assistant professor in the Civil Engineering department, Dr. Abelaal studies geomembranes: low permeability-synthetic materials that look similar to thick garbage bags, that are used to prevent seepage within a variety of industrial settings. Given the high economic and environmental stakes associated with industrial leakage, Dr. Abdelaal says caution and due diligence are necessary before selecting a material for use in a given job.

“I would say the biggest challenge is how much time is needed to assess geomembrane performance, and get reliable estimates of their resistance to degradation,” he said. “If you are buying a product that you want to last for 500 years, you want to get some insight into how it will behave in that 500 years.” Dr. Abdelaal recommends approximately one year of assessment and planning before implementing a material during the construction phase.

Geomembranes are a central component of waste containment facilities, and here in Ontario where existing landfills are rapidly approaching capacity, some of Dr. Abdelaal’s findings could mean that future facilities in this province are better constructed. “Our team’s research could result in better, more durable systems,” he said.

In order to gain a better understanding of how certain geomembranes will hold up in the field, Dr. Abdelaal subjects them to rigorous stress-tests in his lab at Queen’s. In 2019, for his research on the effect of chlorine on geomembrane degradation, he was awarded the Geosynthetics International Award for the best paper published in the journal that year. The research is especially applicable for those involved in the transport of potable water, in which the chemical is used as a disinfectant.

“Even if it’s not very harmful to the environment, it’s a big economic loss if the geomembrane keeps leaking your stored water,” he said.

Dr. Abdelaal’s research also extends into situations that pose a much higher risk to the environment and human health.

“A few months after my appointment at Queen’s, I became involved in an industry project looking at the performance of geomembranes with low-level radioactive waste,” he said. “I did experimental work that would allow the client to choose the product that would give them the best performance.”

“Dr. Abdelaal has an outstanding aptitude for exploring and explaining the scientific principles of the mechanical-chemical-material interactions affecting waste containment systems, and a wonderful ability to explain the engineering context of that science,” said Dr. Ian Moore, Civil Engineering Department Head. “His intellectual investments with his graduate students and collaborators will lead to very long-term benefits for our environment.”

This is not the first time Dr. Abdelaal has been tasked with applying his research in a high-stakes industrial setting.

After graduating with a degree in civil engineering from Ain Shams University in Egypt in 2004, he was given the opportunity to pursue a master’s degree in the field of geotechnical engineering. He says most of his colleagues were working on things like soil/structure interactions and foundation design, while he sought to differentiate himself by focusing on geoenvironmental engineering. The decision was based, in part, on what he saw as a need for local waste management solutions.

“Egypt is a very big country with a very large population that produces a lot of waste,” he said, “Back then we had a lot of resources, but not a lot of expertise in the field.”

Dr. Abdelaal was tasked with improving operations at a poorly designed dumping site that was posing a hazard to its employees and the surrounding environment. “There was a lot of risk to the workers, there were even fatalities, because the site was not engineered and it was poorly managed,” he said.

He and his team managed to impose a series of operational reforms, like constructing roads leading to designated dumping areas, and better protective gear and training for workers. He says that educating the worker’s and convincing them to change their entrenched habits was not easy. “I was only 23 years old. I had to establish leadership and authority over people who were double my age.” In addition to his work at the site, Dr. Abdelaal completed his master’s thesis investigating the use of a mixture of sand and a type of clay called bentonite for use as a barrier soil at municipal landfills.

Equipped with firsthand experience in the design and operation of municipal waste containment facilities, Dr. Adbelaal came to Queen’s University to complete his PhD under the supervision of professors R. Kerry Rowe and Richard Brachman. In 2013 he received the doctoral degree for his research into the chemical resilience of plastic geomembranes for use in municipal landfills.

After graduating, he completed a two-year post-doctoral fellowship where he investigated the safety and efficacy of emergent geomembrane applications in the containment of nuclear and mining waste. He then returned to work at his alma mater, Ain Shams University, for two years until 2017, when he was given the opportunity to return to Queen’s as an assistant professor.

Since then, Dr. Abdelaal has continually worked to expand his research into new domains, including a novel type of containment barriers called bituminous geomembranes. “These are geomembranes, but made up of bituminous materials, like asphalt, instead of plastic,” he said. Part of evaluating the efficacy of these materials is determining their diffusive properties. “The transport of contaminants is not only through leakage or holes. They can diffuse through an intact geomembrane to the underlying environment,” he said. “We need to understand this process for bituminous membranes.”

In addition, he’s working to quantify an important physical property of plastic and bituminous geomembranes: shear strength. “These containment facilities are built with slopes, and sometimes these slopes are steep to reduce the footprint of the industry,” he said. “In that case, the shear strength or interface shear strength of the geosynthetic materials on these slopes becomes a really important design criteria.”

Dr. Abdelaal and his team are also looking at ways of monitoring the performance of geomembranes that are already deployed in the field under harsh conditions, like at facilities above the Arctic Circle. “We are trying to use clean-tech methods to monitor geomembranes in frozen ground,” he said. “We want to see if there is leakage or holes in the geomembrane, but more importantly we want to monitor the behavior of the liner over its service life.”

He currently has five PhD students working in his lab, with another due to join them soon. “Most engineers come to civil engineering and think that it’s just building structures, it usually takes some time for them to realize there are other aspects that are equally important, such as environmental or geotechnical engineering,” he said.

He says he’s encouraged by the amount of interest he sees in his research among industry members. Every year, Dr. Abdelaal along with his former PhD supervisors, professors Rowe and Brachman, organize a workshop where they disseminate their latest research in waste containment strategies. Attendees come from all over Canada and the United States, and even from as far as Europe, to hear about the latest updates in the field before they’ll appear in academic journals.

“Dealing with waste in the past has caused a lot of catastrophic problems, such as the Love Canal incident,” he said. “While we need resource extraction for our industries to proceed, we need to ensure that these processes are done in a safe way for our environment.”