As we plan to electrify more parts of our economy and build new infrastructure, we need more minerals like copper, lithium, and rare earth elements. One way to get them is to mine them, but that can be expensive and hard on the environment. Plus, you have to find effective ways to purify them.

Another way to get those minerals without digging in the ground is by recycling the minerals that have already been extracted, mined, and put into consumer products.

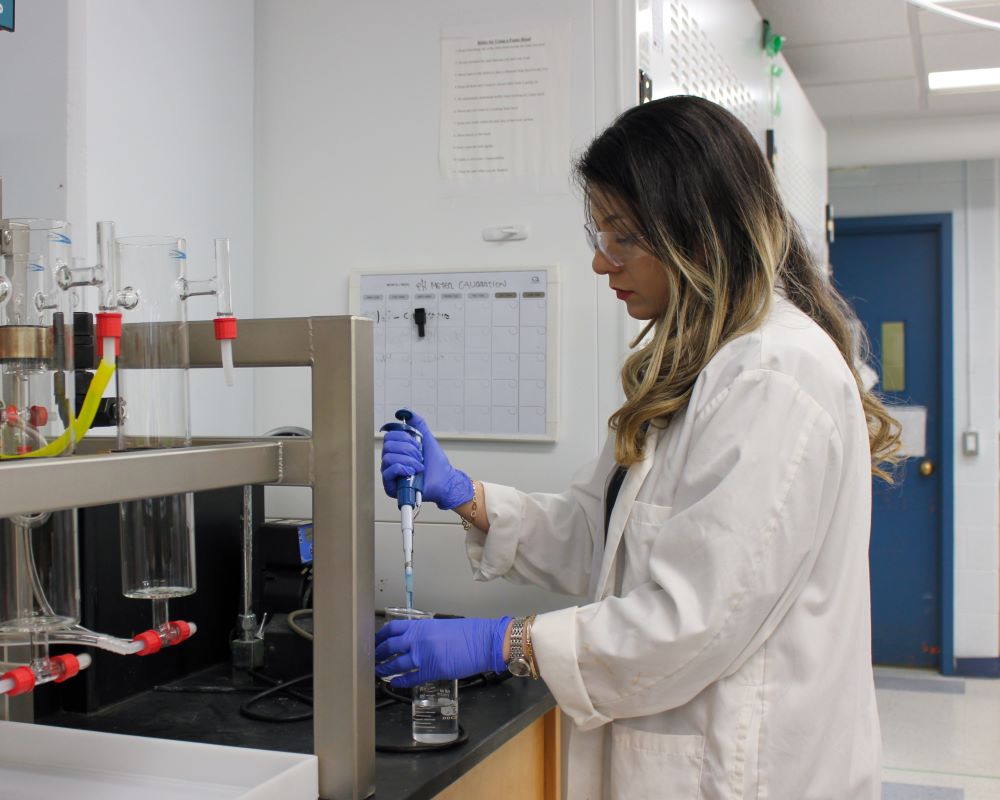

That’s where researchers like Farzaneh Sadri (PhD’19) come in. Sadri works in aqueous extractive metallurgy, where chemical reactions play a pivotal role in extracting metals from ores, concentrates, and even end-of-life products through recycling, using water-based solutions.

Sadri’s interest in the field began in her undergraduate studies in Iran, looking at material science and engineering. Harnessing her interest in chemistry, she focused on hydrometallurgy, a field of metallurgy that uses liquids to help extract metals from resource materials.

“Hydrometallurgy really intrigued me because it's the application of chemistry into something which is very practical,” she says. “We basically need metals for everything.”

She sought international experience upon earning her graduate degree, and chose Queen’s University for her PhD, drawn by the renowned hydrometallurgy group within The Robert M. Buchan Department of Mining.

“My thesis looked at impurity removal during the rare earth elements extraction process and how we ensure we don’t lose rare earth elements during the impurity removal step,” she says. “I looked at the mechanism for this loss and how to recover the rare earth elements, making it more of a circular process. So I devised a process using reagents to minimize the loss.”

After completing a postdoctoral position at Queen’s, where Sadri studied gold recovery and lithium-ion batteries recycling, she joined the Chemical and Materials Engineering department at the University of Alberta as an Assistant Professor in 2022. After that, she made the deliberate choice to return to Queen’s. Recognizing her PhD and Postdoctoral experience so rewarding, she’d come to identify this campus as her “second home,” citing the university's strong engineering reputation globally and the well-equipped labs within the mining department. The appeal in returning to Queen’s was bolstered by Sadri’s appointment as a Canada Research Chair (CRC) Tier 2 nominee, focusing on the chemical extraction of critical metals.

Upon rejoining Queen’s University in October of 2023, Sadri started building her research group, focusing on fundamental research to unlock unknowns in the chemical reactions associated with metal processing. Her long-term goal is to further explore more environmentally responsible techniques for extracting critical metals, with a primary focus on recycling from end-of-life products and mining wastes. This emphasis aligns with the growing demand for critical metals in advancing technologies and meeting net-zero emission goals.

“I want to devise new techniques to prevent some of the harms these processes can cause to the environment, and to minimize the reagents that we are using in these processes to make the processes more environmentally friendly and also more economic,” she says. “Recycling these elements from the end-of-life products was not deemed that important in previous years, but with the very significant increase in the need for advanced technologies and the energy transition there is huge demand for these metals.”

“The increasing production of end-of-life wastes can be harmful to the environment if not treated. Thus, there is a need to recover wealth from the substantial waste at our disposal, serving a dual purpose of both environmental conservation and resource reclamation.”

Sadri is currently teaching undergraduate chemistry for engineering students, emphasizing the importance of extractive metallurgy in the current and future landscape of the mining industry. She intends to teach additional courses focused on mineral processing, hydrometallurgy, and chemical extraction of metals for both undergraduates and graduate level students in the future.

“This field is not well-known to our undergraduate students, and yet between the massive increase in the production of the critical metals and the very rich resources available in this country, there could be a very, very bright future for some of these students,” Sadri says. “This is an interdisciplinary field that connects chemistry, chemical engineering, geology, and material science together and there are great opportunities in the years ahead in the mining industry.”